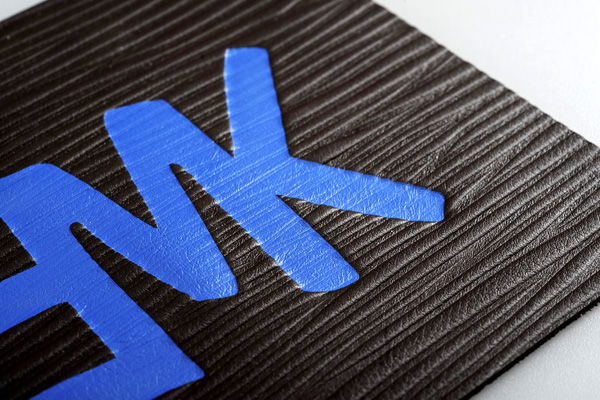

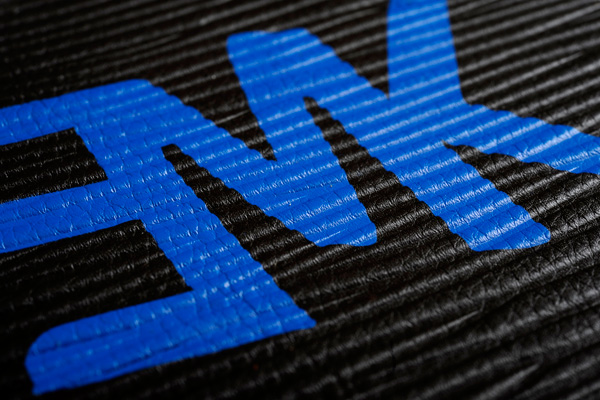

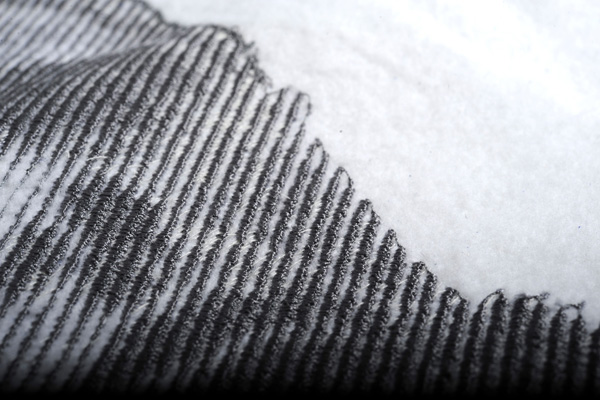

HIGH FREQUENCY

This technique can be used to create a variety of three-dimensional effects, in relief and bas-relief, on logos, designs, shapes and textures, and can be combined with other processes such as screen printing, pad printing and digital printing.

The applications for high frequency engraving are many: labels, patches, padding, personalisation of small/medium leather goods, sneakers and garment details.

We can print large panels up to 50x75cm using our machinery.

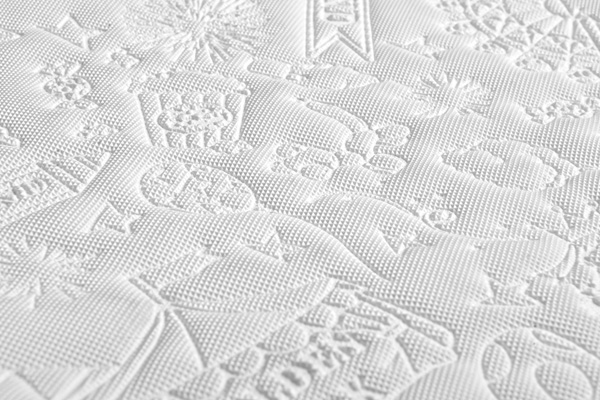

HIGH FREQUENCY

This technique can be used to create a variety of three-dimensional effects, in relief and bas-relief, on logos, designs, shapes and textures, and can be combined with other processes such as screen printing, pad printing and digital printing.

The applications for high frequency engraving are many: labels, patches, padding, personalisation of small/medium leather goods, sneakers and garment details.

We can print large panels up to 50x75cm using our machinery.

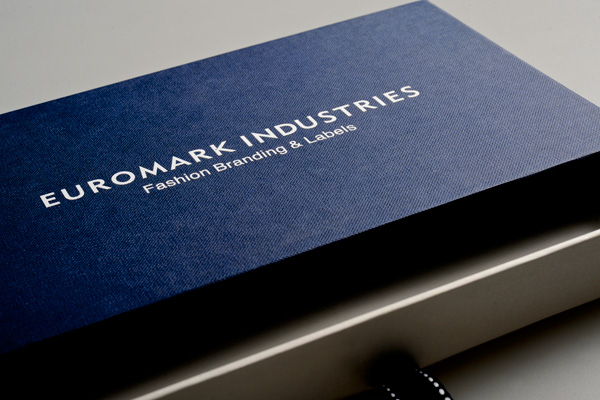

HOT PRINTING

Hot stamping has always been one of the most widely used processes to confer personality, three-dimensionality, and durability to a product.

Using a magnesium, brass, or steel cliché, expertly engraved and properly heated, prints can be made on surfaces such as leather, polyurethane, wood, and linen.

Hot stamping is mainly used in the fashion industry to produce labels, accessories, and bags. Euromark can also handle large panels, up to 50x70 cm size.

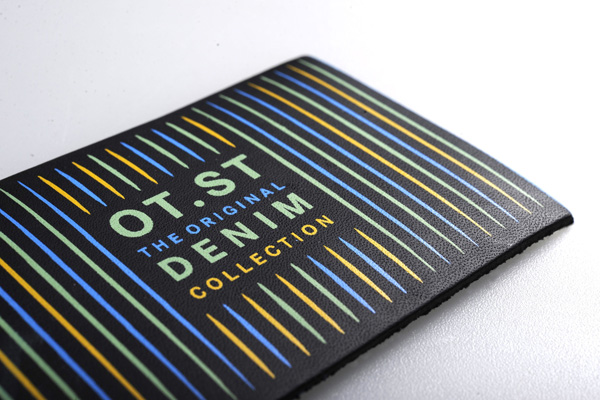

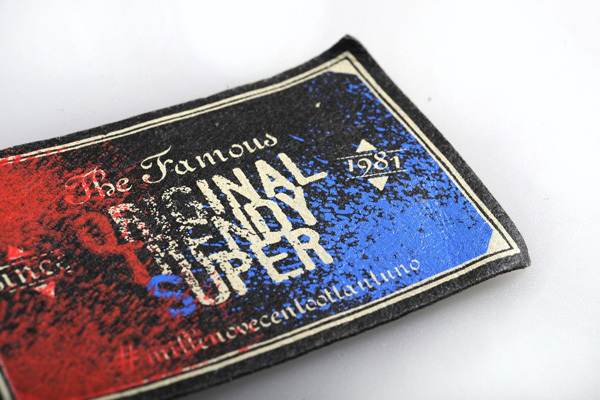

SERIGRAPHY

Thanks to its versatility, we use this technique in all sectors: clothing, footwear, leather goods, etc.

Suitable for a variety of materials (leather, faux leather, fabrics and other types of product), screen printing offers a wide range of creative visual effects. In fact, we have several machines with 4.0 technology that allow us to experiment with new ideas and colour combinations using special inks such as rubberised, iridescent, metallic and UV inks.

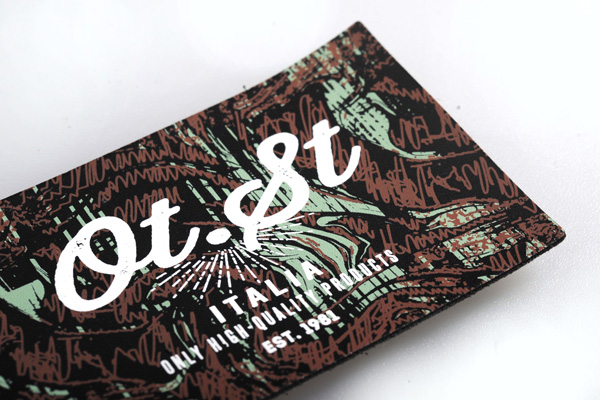

SERIGRAPHY

Thanks to its versatility, we use this technique in all sectors: clothing, footwear, leather goods, etc.

Suitable for a variety of materials (leather, faux leather, fabrics and other types of product), screen printing offers a wide range of creative visual effects. In fact, we have several machines with 4.0 technology that allow us to experiment with new ideas and colour combinations using special inks such as rubberised, iridescent, metallic and UV inks.

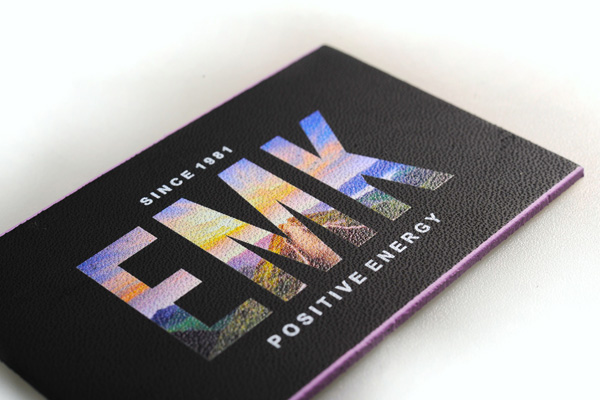

DIGITAL

Direct, fast, and flexible printing method that allows you to personalise different types of materials with optimal image and colour reproduction.

At Euromark we have digital printers that allow us to process both small and large quantities.

Our machines use UV inks that are particularly suitable for printing on leather and can withstand several physical test cycles such as the Martindale Abrasimeter, the Veslic Abrasimeter and the Bally Flexometer.

The advantage of this technique is the speed and variety of cost-effective proposals.

Euromark also has experience and expertise in digital printing of variable data: text, graphics and images can be customised for each printed page using data from external files or databases.

TAMPOGRAPHY

Pad printing is an indirect printing process based on the technology of transferring ink through a silicone pad.

It can be used to reproduce designs, lettering, and decorations, particularly on irregular, concave, or convex surfaces.

We are equipped with an automatic printing machine with a maximum size of Ø 180 mm, in 6 colours.

TAMPOGRAPHY

Pad printing is an indirect printing process based on the technology of transferring ink through a silicone pad.

It can be used to reproduce designs, lettering, and decorations, particularly on irregular, concave, or convex surfaces.

We are equipped with an automatic printing machine with a maximum size of Ø 180 mm, in 6 colours.

OFFSET PRINTING

Offset printing is mainly used to produce paper tags, pocket covers, paper easels, cards, and derivatives.

It is an indirect method of printing: the image is created on a master plate, then transferred onto a rubber backing and through this imprinted onto the sheet.

The rubber allows even surfaces that are not exactly smooth, such as certain types of paper, to be printed with great precision.

The machines we have also allow us to print on cardboard up to a grammage of 700 gsm.

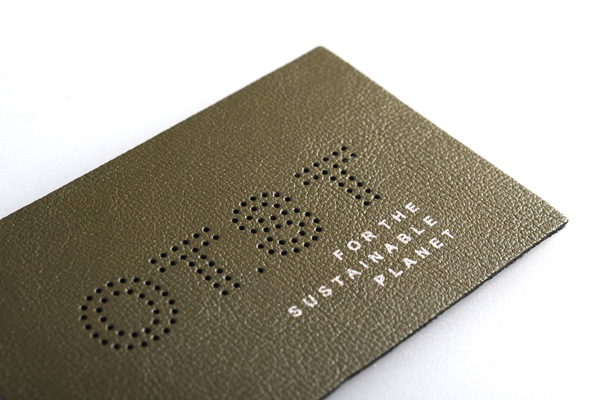

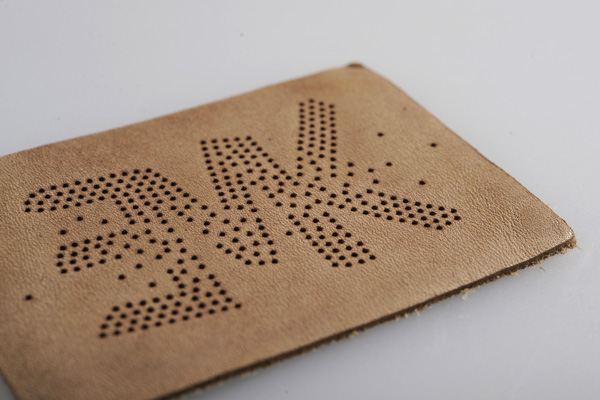

MICRO-DRILLING

This is an innovative technique developed with 4.0 machines.

It allows the processing of leather and synthetic materials and is an alternative to the classic laser.

The machine we use allows us to drill holes in materials with a thickness of 1/1.2 mm with holes having a minimum diameter of 0.8 mm.

MICRO-DRILLING

This is an innovative technique developed with 4.0 machines.

It allows the processing of leather and synthetic materials and is an alternative to the classic laser.

The machine we use allows us to drill holes in materials with a thickness of 1/1.2 mm with holes having a minimum diameter of 0.8 mm.

LASER

We offer customised laser processing on leather, textiles, and other materials, using a high-precision machine for cutting, marking, and engraving.

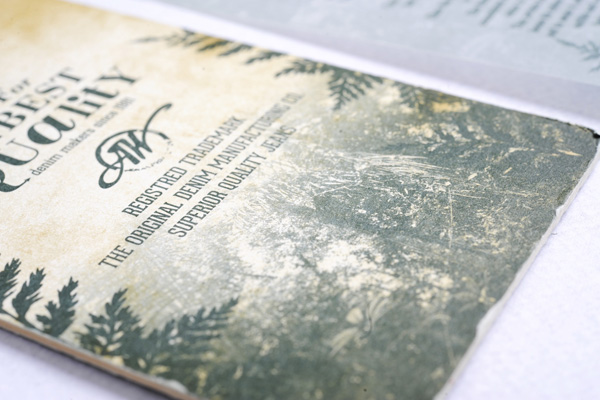

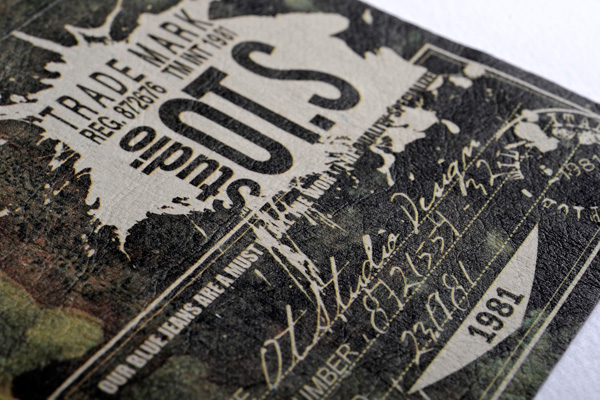

LAUNDRY

In this department we can give products a vintage look by using different types of washing, craft techniques and multiple dyeing.

LAUNDRY

In this department we can give products a vintage look by using different types of washing, craft techniques and multiple dyeing.

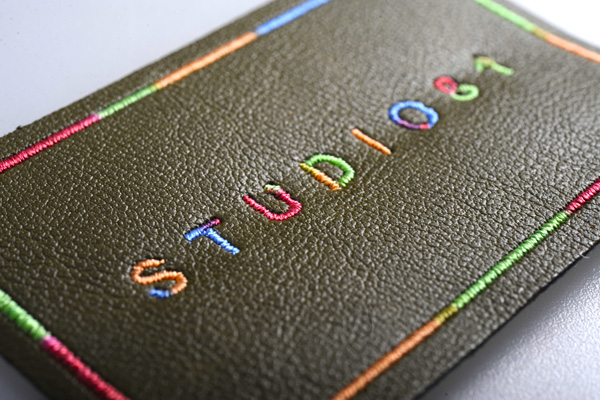

SPECIAL PROCESSING

Euromark assists its customers by carrying out research and special processing and by producing customised products of various types, based on know-how gained from many years of experience.

Examples of special finishes on request are: embroidery, transfers, strass, rivets, studs, and dye-edge, to name but a few.